I've got a 4x4 parked outside but the Dana 20 transfer case (the component which allows you to select between 2WD and 4WD low/high) doesn't work. Would-be perpetrators will want to watch out for me, even if I'm stuck in two-wheel drive. Keith from the scout shop said he even tried pushing on the lever with his legs.

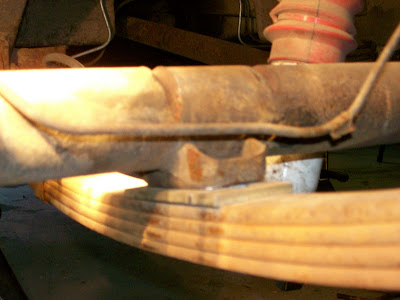

That's the thing about the the scout, it's more like driving a tank than a passenger car. You can push levers as hard as you want. This is a three-speed/reverse unsynchronized manual transmission:

- The earliest automotive transmissions were entirely mechanical unsynchronized gearing systems. They could be shifted, with multiple gear ratios available to the operator, and even had reverse. However, the gears were engaged by sliding mechanisms or simple clutches, which required careful timing and throttle manipulation when shifting, so that the gears would be spinning at roughly the same speed when engaged; otherwise, the teeth would refuse to mesh.

When upshifting, the speed of the gear driven by the engine had to drop to match the speed of the next gear; as this happened naturally when the clutch was depressed or disengaged, it was just a matter of skill and experience to hear and feel when the gears managed to mesh. However, when downshifting, the gear driven by the engine had to be sped up to mesh with the output gear, requiring letting the clutch up (engagement) for the engine to speed up the gears. Double declutching, that is, shifting once to neutral to speed up the gears and again to the lower gear, is sometimes needed. In fact, such transmissions are often easier to shift without using the clutch at all. When using this method, the driver has to time the shift with relative precision to avoid grinding the gears. The clutch, in these cases, is only used for starting from a standstill. This procedure is common in racing vehicles and most production motorcycles.

Even though automotive transmissions are now almost universally synchronised, heavy trucks and machinery as well as dedicated racing transmissions are usually non-synchromesh transmissions, known colloquially as "crashboxes", for several reasons. The friction material, such as brass, in synchronizers is more prone to wear and breakage than gears, which are forged steel, and the simplicity of the mechanism improves reliability and reduces cost. In addition, the process of shifting a synchromesh transmission is slower than that of shifting a non-synchromesh transmission. For racing of production-based transmissions, sometimes half the teeth (or "dogs") on the synchros are removed to speed the shifting process, at the expense of greater wear.

This means downshifting is difficult, but it doesn't bother me because when these gears grind it sounds like, "sorry, you have made an incorrect selection. please select a different gear." There are metal-on-metal sounds but it's BIG TOUGH metal gears refusing to mesh with BIG TOUGH metal gears at high RPM.

I know what you'll say, I should get a tractor.